Badcock And Wilcox Boiler Ppt Background

- Diagram For Babcock And Wilcox Boiler

- Babcock And Wilcox Boiler Working

- Babcock And Wilcox Boiler Drawings

Background The company was. Rhode Island, residents Stephen Wilcox and his partner George Herman Babcock patented the Babcock & Wilcox Non-Explosive Boiler. Babcock and Wilcox Boiler. Terry Babcock Lumish Presentation. Gregory Babcock Conditions of Release. Gregory Babcock Drug trafficking Admission.

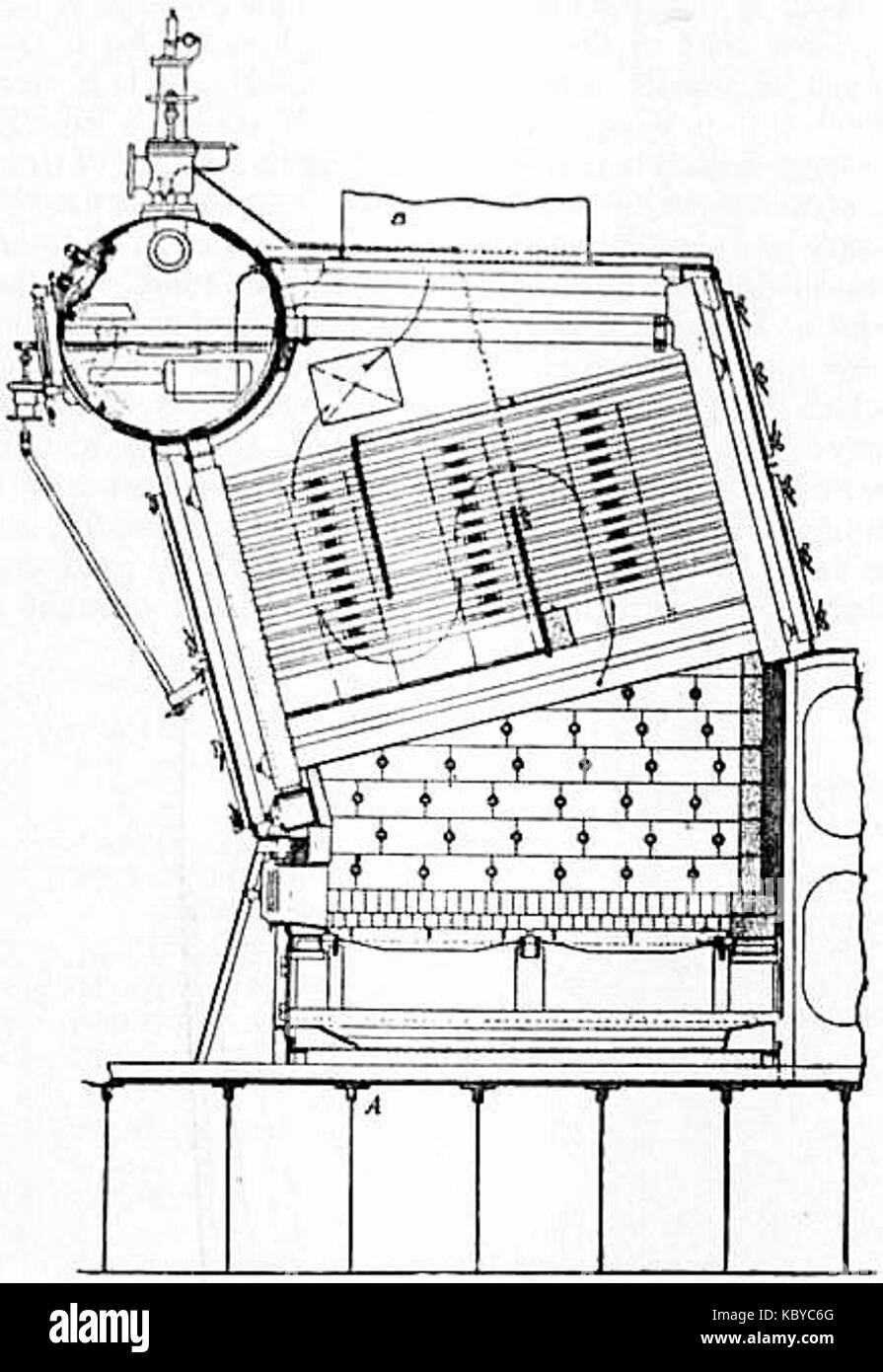

Construction of babcock and wilcox boiler. 1. Construction of Babcock and Wilcox BoilerThe Babcock and Wilcox Boiler consists of 1.

Steam and water drum (boiler shell) 2. Water tubes 3. Uptake-header and down corner 4. Super heater 8. Inspection door 10. DamperSteam and water drum (boiler shell):One half of the drum which is horizontal is filled up with water and steam remains on theother half. It is about 8 meters in length and 2 meter in diameter.Water tubes:Water tubes are placed between the drum and furnace in an inclined position (at an angle of10 to 15 degree) to promote water circulation.

These tubes are connected to the uptake-headerand the down-comer as shown.Uptake-header and down-corner (or downtake-header)The drum is connected at one end to the uptake-header by short tubes and at the other end tothe down-corner by long tubes. Grate: Coal is fed to the grate through the fire door.Furnace: Furnace is kept below the uptake-header.Baffles: The fire-brick baffles, two in number, are provided to deflect the hot flue gases.Superheater: The boiler is fitted with a superheater tube which is placed just under the drumand above the water tubesMud box: Mud box is provided at the bottom end of the down comer. The mud or sedimentsin the water are collected in the mud box and it is blown-off time to time by means of a blow–off cock.Inspection doors: Inspection doors are provided for cleaning and inspection of the boiler.Working Babcock and Wilcox Boiler:Coal is fed to the grate through the fire door and is burnt.Flow of flue gases:The hot flue gases rise upward and pass across the left-side portion of the water tubes. Thebaffles deflect the flue gases and hence the flue gases travel in the zig-zag manner (i.e., thehot gases are deflected by the baffles to move in the upward direction, then downward andagain in the upward direction) over the water tubes and along the superheater.

The flue gasesfinally escape to atmosphere through chimney.Water circulation:That portion of water tubes which is just above the furnace is heated comparatively at ahigher temperature than the rest of it. Water, its density being decreased, rises into the drumthrough the uptake-header.

Here the steam and water are separated in the drum. Steam beinglighter is collected in the upper part of the drum. The water from the drum comes downthrough the down –comer into the water tubes.A continuous circulation of water from the drum to the water tubes and water tubes to thedrum is thus maintained.

Diagram For Babcock And Wilcox Boiler

The circulation of water is maintained by convective currents and isknown as “natural circulation”.A damper is fitted as shown to regulate the flue gas outlet and hence the draught.The boiler is fitted with necessary mountings. Pressure gauge and water level indicator aremounted on the boiler at its left end. Steam safety valve and stop valve are mounted on thetop of the drum. Blow-off cock is provided for the periodical removed of mud and sedimentscollected in the mud box.Salient features of Babcock and Wilcox Boiler:. 1. Its overall efficiency is higher than a fire tube boiler. The defective tubes can be replaced easily.

All the components are accessible for inspection even during the operation. The draught loss is minimum compared with other boiler. Steam generation capacity and operating pressure are high compared with other boilers. The boiler rests over a steel structure independent of brick work so that the boiler may expand or contract freely. The water tubes are kept inclined at an angle of 10 to 15 degree to promote water circulation.Advantages and disadvantages of water tube boilers overfire tube boilers:Advantages water tube boilers 1. Steam can be generated at very high pressures.

Heating surface is more in comparison with the space occupied, in the case of water tube boilers. Steam can be raised more quickly than is possible with a fire tube boiler of large water capacity. Hence, it can be more easily used for variation of load. The hot gases flow almost at right angles to the direction of water flow.

Hence maximum amount of heat is transferred to water. A good and rapid circulation of water can be made. Bursting of one or two tubes does not affect the boiler very much with regard to its working. Hence water tube boilers are sometimes called as safety boilers.

The different parts of a water tube boiler can be separated. Hence it is easier to transport.

It is suitable for use in steam power plants (because of the various advantages listed above).Disadvantages of water tube boilers 1. It is less suitable for impure and sedimentary water, as a small deposit of scale may cause the overheating and bursting of tubes. Hence, water treatment is very essential for water tube boilers.

Maintenance cost is high. Failure in feed water supply even for a short period is liable to make the boiler overheated.

Hence the water level must be watched very carefully during operation of a water tube boiler.

Large-Scale Utility Power Shortly after our establishment in 1867, Babcock & Wilcox designed the world's first installed utility boiler. B&W boilers now provide more than 300,000 MW of generating capacity in approximately 60 countries.

Babcock And Wilcox Boiler Working

In 1957 when B&W built the world's first commercially operated supercritical boiler, our designs were instrumental in the advancement of power generation efficiency. Since then, we've designed and constructed the first U.S. Ultra-supercritical power plant using technology representing the most advanced steam cycle conditions commercially available today. Pulp & Paper Process Recovery Many decades ago, B&W placed into service the first “black liquor” recovery boiler in the U.S. Which used a by-product of the pulping process as fuel. With one of the largest installed base in the world of more than 350 recovery boilers, B&W is committed to the pulp and paper industry by helping today's energy-intensive mills. Renewable Energy When we developed our first waste-to-energy plant in 1930, it revolutionized waste disposal techniques.

Babcock And Wilcox Boiler Drawings

Over the years. B&W and Babcock & Wilcox Volund waste-to-energy, biomass and multi-fuel technologies have been incorporated in more than 500 production lines in more than 30 countries.