Carburetor Jetting Software Piracy

Technical article about jetting theory for a rotax. Uranus Software. It's also important to remembered that carburetor jetting is determined. 2 Stroke Carburetor adjustment procedure for off-road. Stroke carburetors this is an air screw so don’t. Throttle opening range of each jet in the carburetor.

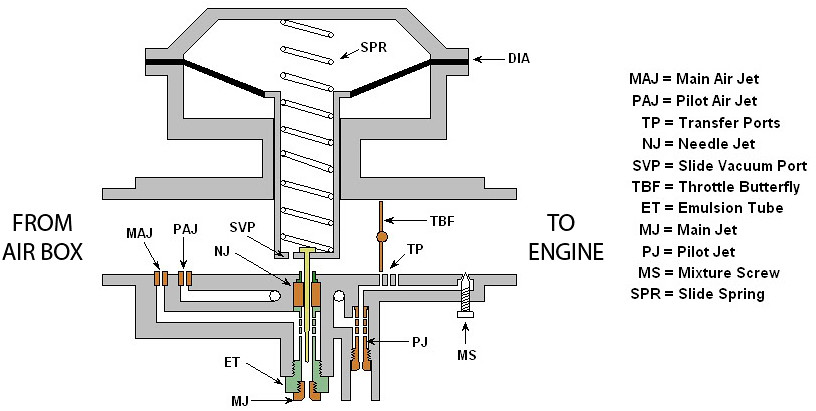

Rotax MAX Dellorto Carburetor The carburetor is one of the most important parts in a karting engine. It's main function is to form a 'proper' homogeneous inflammable mixture of fuel and air.

Keihin Carburetor Jetting

This fuel-air mixture is formed through vapourising and by uniformly spraying fuel into the airstream or at least by atomising it into very small droplets. In order to get this 'proper' mixture of gas and air, several adjustments has to be taken into consideration, as venturi insert size, floats weight, floats height, needle, jets (main, idlle, chocke), etc. For the Rotax Max engines family some of this adjustments are fixed by the regulations, as the venturi size, floats height, idle or chocke jets, etc. So in order to get the 'proper' air/fuel mixture, only a few changes can be made. In a Rotax engine, this is the standard configuration (in some countries, different rules can apply, please, always verify your local regulations for Rotax racing).

There isn't a whole lot to a carburetor from a parts perspective, but knowing how each of the components effect each other is crucial when it comes to tuning a carburetor. Modern fuel injected engines deliver precise air/fuel ratios which allow for good power and drivability, while at the same time netting impressive gas mileage.

A large part of that success is due to modern-day engine management systems, where a variety of sensors inform the computer of current engine operating conditions, so it can make accurate fuel calculations. The same technique can be used to tune a carbureted engine. All that is needed are a few key sensors, and a method of recording their readings over time. Let’s take a look at some basic sensors for this process. RPM Signal An engine speed signal can come from the negative side of the coil, a tach output from an aftermarket ignition box or factory ignition module, crank trigger, or an inductive pickup of some sort.

Viewing the RPM graph in a datalog gives us a quick visual reference of where we stand. Wideband O2 Sensor By detecting the amount of unburned oxygen content in the exhaust after combustion, a wideband sensor is able to indicate the engine’s actual air/fuel ratio. This tells us how rich or lean the engine is from stoichiometric. The stoich air/fuel ratio for standard gasoline is around 14.7:1 (lambda 1.00). Consider this to be the chemically correct air/fuel ratio to completely burn all available oxygen during combustion, leaving no air or fuel left over afterwards. Though stoich is ideal for many circuits of operation, it is typically too lean at wide open throttle for the vast majority of engines and will be most happy between 12:1-13.5:1. Don't be persuaded by bad tuning; carburetor-powered vehicles can benefit from EFI-like drivability as well.

Once considered too expensive for the average enthusiast, wideband kits have become surprisingly affordable in recent years. Look for a kit that has good datalogging software, several analog inputs, RPM input, free air calibration, and analog output. An in-car display is also nice, and mandatory if the software does not display the air/fuel ratio in real time. For this example, we used LM-1. This is the older version to their newly updated that is two channel capable and records directly onto the included SD card. Even Factory-Supplied Sensors Help Many factory sensors, including those listed below, output a signal ranging from 0 – 5 volts depending on the sensor readings. In order to use these sensors, we have to supply them with a five-volt power source, an engine ground, and a signal wire to one of our datalogger‘s analog inputs.

To reduce the vehicle’s 12 volt power down to the required five volts, use an LM7805 voltage regulator. They’re available from electronics stores for a very modest price. The TPS is a potentiometer that measures rotation of the throttle shaft. The sensor puts out between 0 and 5 volts linearly, depending on throttle position. In reality, these sensors are at their idle position between.5 and 1 volt, and register full throttle around 4.5 volts. We’ll plug the signal wire into one of the wideband’s analog inputs. A clever mind can easily adapt a TPS to the end of a Holley primary throttle shaft.

Measuring manifold pressure will help tuning different parts of the load cycle GM makes good, inexpensive MAP sensors. They measure the absolute pressure inside the intake manifold. While we normally think of vacuum and boost as being on two different sides of the atmospheric pressure line, the MAP sensor simply sees vacuum as a positive absolute pressure and boost as just a higher positive pressure. MAP sensors are available in one, two or three bar versions. The one bar has the best resolution for a naturally aspirated motor, while a two bar is good for 14 pounds of boost, and a three bar goes up to 29 PSI.

Mikuni Carburetor Jetting

● GM 1 bar MAP Sensor part# 12569240 ● GM 2 bar MAP Sensor part# 12569241 ● GM 3 bar MAP Sensor part# 12223861 Identifying the Carburetor’s Circuits of Operation Now that we have a good understanding of the tools available, let’s take a look at what we’re trying to achieve. Holley carburetors have four distinct circuits of operation: idle, off-idle, cruise, and wide open throttle. They also have an accelerator pump to compensate for quick throttle actuation. Idle – At idle speed, the carb runs solely on the curb idle discharge port.

Air/fuel ratio is adjusted by turning the idle mixture screws. Target an air/fuel ratio of stoich (14.7:1 – lambda 1.00) for standard gasoline. Engines with longer duration camshafts may not be able to maintain good combustion this lean.

If necessary, you can richen it up to as much as 13.5:1 (lambda.92). Try to achieve the highest manifold vacuum you can, at the leanest ratio that provides stable combustion. Set idle speed as low as reasonably possible to avoid entering the off-idle circuit. Off Idle – Just above idle at very light throttle positions, the transfer slot now provides the fuel. Idle feed restrictions and idle air bleeds are used to tune this circuit. The elevated RPMs should allow us to maintain a 14.7:1 (lambda 1.00) air/fuel ratio, even with a lopey cam. Engines with very large cams may require a slightly richer mixture.

If the cruise circuit comes in too soon, it can overlap the off-idle circuit too much and cause a very rich condition. You can delay the cruise circuit by enlarging the main air bleeds. The metering block houses the power valve and jets. Primary (front of carburetor) jets are your primary tuning jets for cruising and low throttle use. Moderate and wide open throttle is where the secondaries come into play from a tuning perspective.

Cruise – Around 2000 – 2500 RPM, the transfer slot circuit begins to fade out and the main jets take over all fuel supply duties. Here’s where gas mileage can really be improved! Jet the carb for an air/fuel ratio between 14.7:1 and 15.3:1 (lambda 1.00 – 1.04) in all cases. But don’t lean it out to the point where the engine begins to stumble. WOT – Anything over about half throttle reduces manifold vacuum to a point where the power valve should open. This uncovers the PVCR’s (Power Valve Channel Restrictions), allowing additional fuel enrichment under heavy load. To make maximum torque safely, we need to richen the mixture up some.

A good target would be an air/fuel ratio of 12.5:1 (lambda.85). Modify the PVCR size until your target lambda is achieved. This typically means enlargement. Boosted cars will want to run considerably richer, such as 11.5:1 (lambda.78) or more. Power valves are rated by the amount of manifold vacuum required to close them. Any vacuum amount below this level opens them. The trick here is to size the power valve roughly 1.5-inches below the minimum amount of vacuum your engine produces at idle.

Final Word on Power Valve and Accelerator Pumps Adjustable metering blocks often have changeable PVCR jets. If using regular metering blocks, adjustment is done by modifying the PVCR diameter.

Proper WOT air/fuel ratios could be achieved by enlarging the main jets instead, but that would richen up the cruise circuit beyond ideal. Poor gas mileage and plug fowling will result.

All about plano driver improvement course find out more here. Go to plano driver improvement course in Califonria here. Ads driver improvement course.

Power valves are rated by the amount of manifold vacuum (in inches of mercury) required to close them. Any vacuum amount below this level opens them. The trick here is to size the power valve roughly 1.5-inches below the minimum amount of vacuum your engine produces at idle.

This ensures the power valve will not open prematurely. At the same time, you want the valve to open any time you’re much over half throttle. Comparing MAP and TPS readings will help you find that balance. Accelerator pumps come with a cam adjustment slot for controlling the timing of the accelerator pump and sit right behind the '1, 2' adjustment screw.

Pump cam kits can be purchased to change the rate in which the accelerator pump will ramp in the additional fuel. Accelerator Pump – Anytime the throttle is opened rapidly, manifold vacuum drops and the car momentarily runs lean. Pumping an extra shot of fuel in prevents this lean condition, and instead creates a torque-producing slight rich condition. The air/fuel ratio should richen up for a second or two, and then quickly fade back to your desired ratio without ever going lean. Shoot for a light acceleration air/fuel ratio of 13.8:1 (lambda.94). Full throttle acceleration should produce and maintain your total WOT enrichment ratio (12.5:1 or lambda.85 on a naturally aspirated engine). Change accelerator pump squirter size, pump cam, and pump cam position to tune this circuit.

What Is Software Piracy

Once you install the sensors and build a simple wiring harness for them, set up your laptop for datalogging. For best results, tune the circuits one at a time in the order listed. After using a wideband sensor to tune your carb, you’ll wonder how you ever got along without one.

Before you know it, you’ll be tuning like a pro!